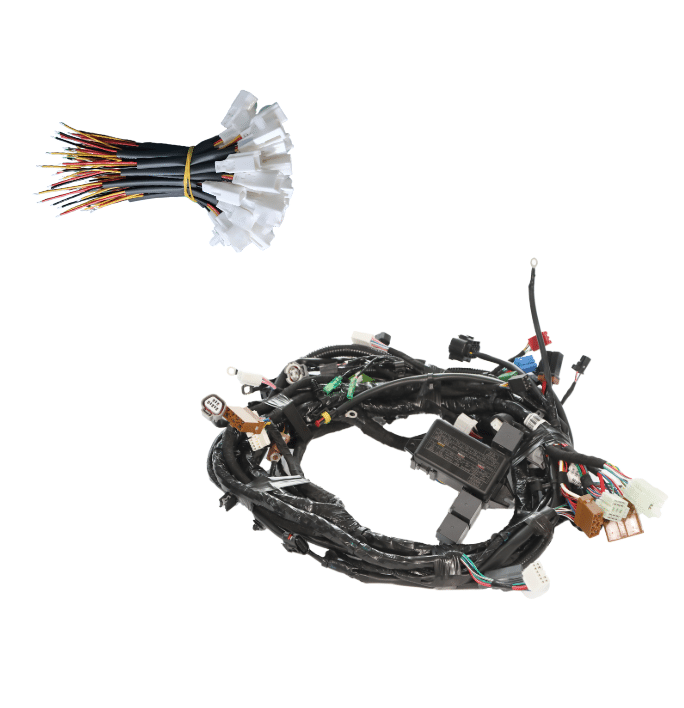

Looking for the best custom wire harness

and cable assembly manufacturing services?

28 Years ODM/OEM Expertise | Rapid Custom Wiring Harness Factory | One-Stop Solutions | Replies Within 8 Hours

Comprehensive Solutions

Production exceeds 300,000 units

Through global precision sourcing, we help you achieve cost control

Customizable Products

One-on-one service tailored to your specific needs

Exclusive services, providing you with tailor-made customized solutions

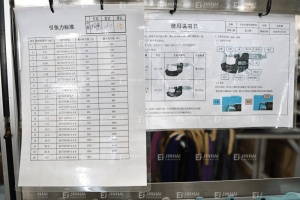

Rigorously Controlled

High Yield Rate | Rapid Prototyping to Final Delivery

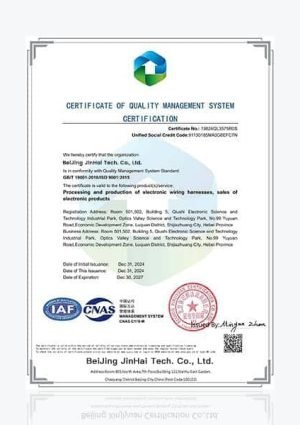

Adhering to the ISO 16949 quality management system standard, we provide 24-hour after-sales support

Contact Us

Custom Wiring Harness and Cable Assembly today.

With 28 years of deep expertise in the wire harness field as an ODM/OEM provider, we deliver all precise, high-quality solutions to meet your business needs.

Choose JinHai to accelerate your project's success—JinHai grows alongside your project!

JinHai's Comprehensive Customization Service Process

As a professional custom wiring harness supplier, JinHai’s customization services accelerate your project success and meet your unique requirements.

20+

Manufacturing Experience

30+

Technical Staff

30+

Serving The Country

JinHai - Custom High Quality Wiring Harness Process

JinHai is responsible for every stage of your project, from design and prototyping to full-scale production.

Determine the application environment and specific requirements

Develop corresponding design solutions based on the specific application environments and other special requirements of the wiring harness.

Review design proposals

Based on the drawings provided by the customer, we identify the materials to ensure the custom wiring harness meets your requirements.

Material Selection

From global standard parts to custom specialty materials, we can provide the raw materials to meet your needs.

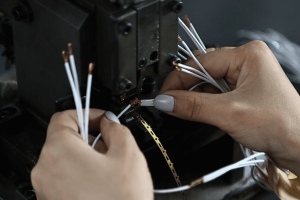

Manufacturing Process

Our advanced manufacturing and inspection equipment form the core of ensuring consistent and stable production throughout critical processes.

Prototype Manufacturing

For prototype samples, conduct 200% inspection on each individual process to ensure physical items match the design specifications.

Mass production

After the prototype samples passed adaptation and testing, we commenced mass production.

If you need custom wire harness manufacturing or OEM services, please choose JinHai as your manufacturer!

Submit A Quick Quote

We develop prototypes based on your practical requirements.

Each wiring harness complies with relevant standards including 3C, CE, UL, IATF 16949, and ISO 9001.

We have a team of experienced design experts to help your project achieve rapid success.

All our terminals undergo cross-sectional analysis control according to product specifications.

JinHai has partnered with brands such as TE, MOLEX, JST, THB, and HIROSE for over 20 years, enabling us to provide rapid global procurement services.

OQC is responsible for 100% loop continuity testing, while PQC conducts re-testing and sampling inspections.

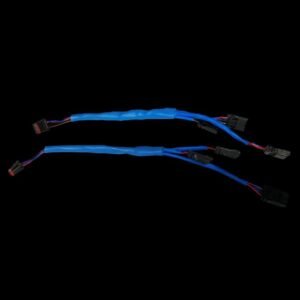

Customized Wire Harness Manufacturing For Different Industries

JinHai can manufacture various types of wire harnesses for your application, just send us your drawings and get our best quote.

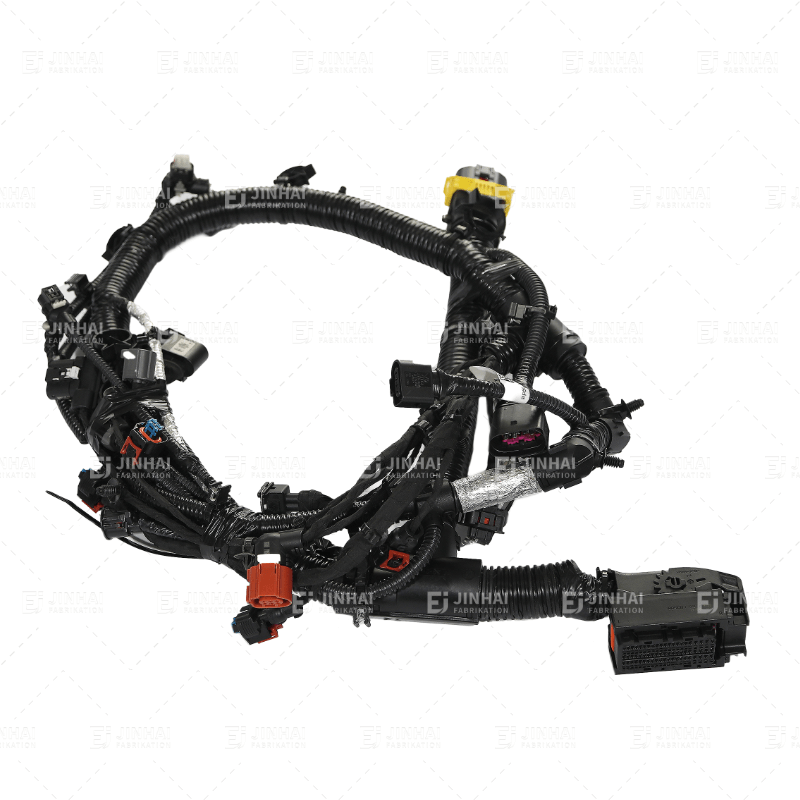

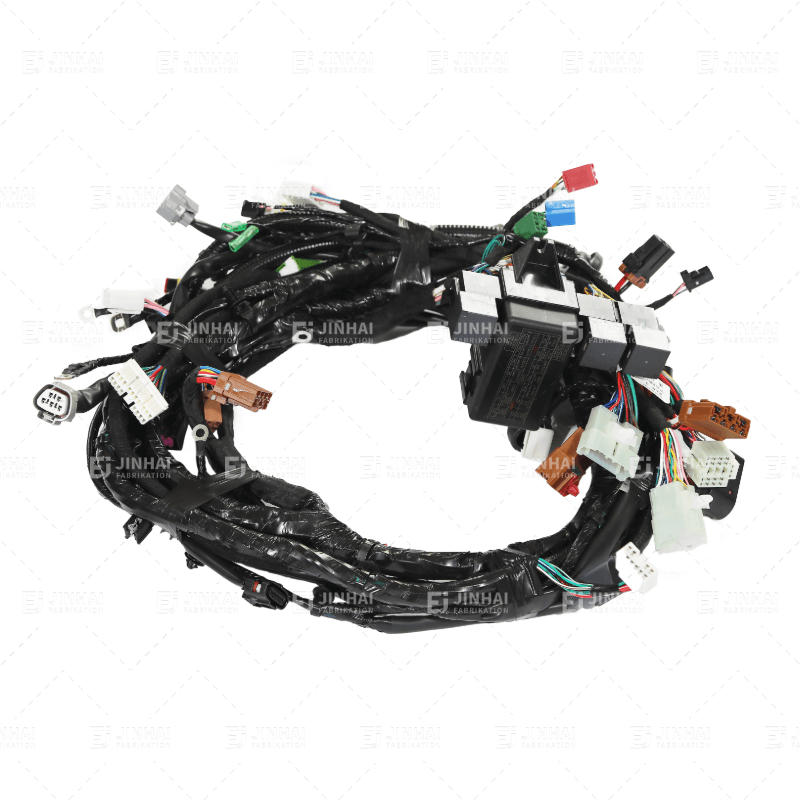

Automotive

Leveraging robust R&D and manufacturing capabilities, Jinhai produces automotive wiring harnesses including engine compartment harnesses, body harnesses, and chassis harnesses.

Motorcycles

Utilizing automotive-grade harness manufacturing expertise, Jinhai manufactures motorcycle wiring harnesses such as head harnesses, body harnesses, and steering harnesses.

Agricultural Machine

Leveraging extensive material expertise, Jinhai provides agricultural wiring harnesses for machinery, including cab harnesses, working equipment harnesses, and sensor harnesses.

Smart Home

Through comprehensive product offerings, Jinhai independently manufactures main power harnesses, motherboard harnesses, motor harnesses, and control panel harnesses.

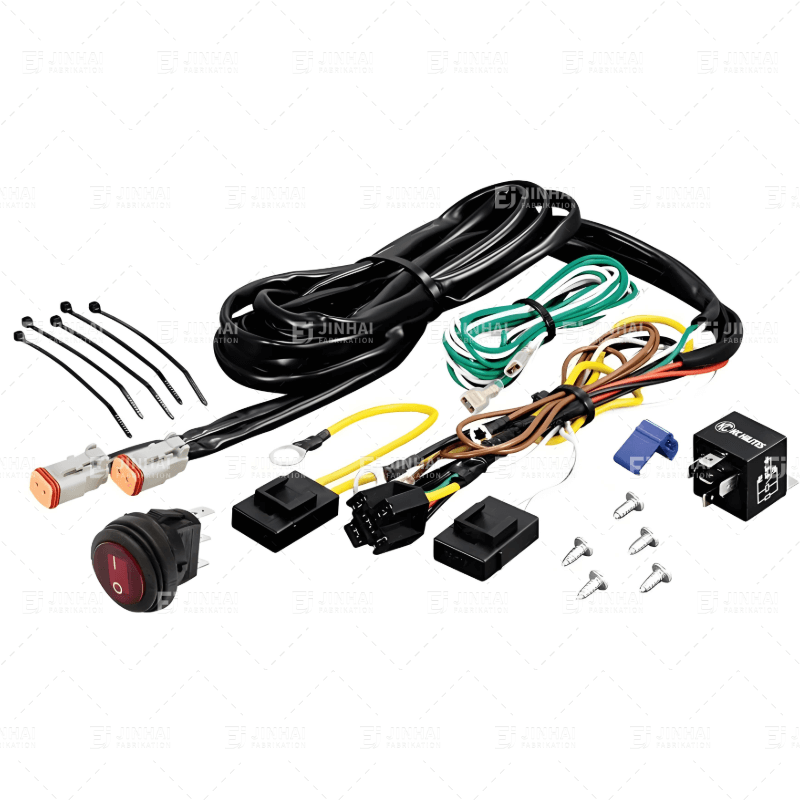

Custom Cable Assemblies

- Cable Assemblies

- Signal Transmission Assemblies

- Drive System Assemblies

- Network System Assemblies

- Switch Assemblies

- Battery Cable Assemblies

- Other Assemblies

Submit A Quick Quote

Why JinHai Is Trusted By 1000+ Clients

Customized services deliver significant benefits to businesses and projects across all industries. Here are the advantages of our services:

Cost-Effective and Rapid Production

We process orders swiftly, centralize raw material procurement, and simultaneously manufacture wire harnesses for multiple sectors. Jinhai ensures consistent product quality while maintaining rapid production. Large-volume and long-term orders enable us to offer more cost-effective wire harness manufacturing services.

Exceptional Flexibility and Lightweight Design

Through our advanced wiring harness manufacturing processes, we employ flexible approaches to elevate harness production to new heights.

Extensive Materials and Technologies

As wiring harness specialists, our robust expertise enables us to produce versatile, high-performance harnesses for systems like steering, instrumentation, and multimedia. Our harness materials withstand extreme temperatures, corrosion, and diverse operating conditions.

Customer-Centric Material Solutions

We strictly adhere to customer-specified materials for production. When no materials are specified, we provide alternative solutions to meet client requirements.

Extensive Business Scope

With superior manufacturing capabilities and a broad production footprint, Jinhai delivers premium wiring harnesses for automotive, agricultural machinery, motorcycle, and home appliance industries.

Other Advantages of JinHai

- Terminal

- Connectors (Sealed/Non-sealed)

- Cable ties (standard/custom shapes)

- Tape (abrasion-resistant/non-abrasion-resistant)

- Fully Automatic Crimping Machine

- C-Type Winding Machine

- Mobile Fixture Board Conveyor System

- Ultrasonic Welding Machine

What Our Customer Say

Our Amazing Clients

For over 20 years, we have worked closely with numerous distinguished clients, supporting each partner in launching new projects and expanding their professional expertise.

What is the minimum order quantity?

At JinHai, we define MOQ based on different harness types. Below are JinHai’s internal minimum order quantities:

- Simple harnesses (consumer electronics or small appliance internal harnesses)

- MOQ: 500–2000 pieces;

- Moderately complex harnesses (industrial harnesses, agricultural machinery harnesses, low-voltage automotive harnesses)

- MOQ: 1,000–5,000 pieces;

- Highly Complex Harnesses (e.g., engine harnesses, chassis harnesses, instrument panel harnesses)

- MOQ: 5,000+ pieces

- Fully Customized Harnesses

- JinHai determines MOQ based on complexity and cost considerations: 2,000–5,000 pieces;

Do you support customized designs?

Yes, we offer full-process customized design services, but require clients to provide clear technical input documents to ensure precise alignment with requirements. Below are the specific requirements and collaboration process:

- Required Input Documents:

- Electrical Schematic: Specify wire gauge, connector models, fuse/relay locations, etc.;

- 2D Layout Diagram: Specify branch dimensions, cable tie attachment points, protective material specifications, and shielding requirements;

- Application Environment Parameters: Indicate operating temperature range, vibration conditions, waterproof rating, and EMC requirements;

- Customization Service Process:

- Our company requires 1-3 business days to confirm the harness’s operating environment, application scenarios, and special requirements;

- After providing 3D simulation drawings and 2D flat patterns, our company requires 5-10 business days for design verification. We can assist with initial revisions and iterations (up to 3 free rounds).

- Sample Production: After design verification, we require 7-15 business days for raw material procurement and sample fabrication. Sample quantity: 1-3 pieces (prototyping fees apply upfront, but can be offset against bulk production costs). Samples shipped with harness appearance and continuity test reports.

- Batch Delivery Cycle: Small batches (>100 pieces) require 15-20 days. Large batches (>1000 pieces) require 30-45 days (partial shipments possible).

- Important Notes

- Drawings require final customer confirmation and signed return for our records;

- Design changes after mass production may incur fees based on the number of change points and complexity;

- We offer cost optimization solutions, e.g., replacing PTFE with XLPE reduces costs by 40%.

Logistics Methods

JinHai offers multiple logistics options:

- International Express Delivery: Ideal for sample shipments. Couriers assist with customs clearance. JinHai currently partners with DHL, TNT, and EMS.

- International Air Freight: Suitable for small-batch product deliveries. Offers faster transit times than sea or rail freight with high security.

- International Sea Freight: The most prevalent shipping method in international trade, suitable for bulk order shipments with flexible containerization options.

- International Rail Transport: Also suitable for bulk order shipments, primarily serving the China-Europe corridor.

Quality Control Measures in Production?

- Incoming Material Inspection

- Wires and terminals are sampled and tested based on the supplier’s shipping report to verify wire strand count, wire diameter, color, terminal plating thickness, and dimensions. Connectors are sampled and tested for dimensional compliance against official drawings.

- Process Inspection

- Wire Cutting/Crimping Process: Initial, patrol, and final inspections are conducted per CP requirements. Patrol inspections occur at a frequency of 2 hours per shift.

- Pre-assembly Process: Insertion follows the “insert, listen twice, pull back” procedure.

- Assembly Process: First, verify seal installation. Second, confirm secondary locking of connectors and primary locking of terminals.

- Final Inspection

- Inspectors conduct 100% dimensional checks of harnesses using tape measures/steel rulers;

- Perform 100% electrical functionality testing on finished harnesses using dedicated harness electrical test benches;

- Quality inspectors conduct final checks on harness appearance, material integrity (clips/tie wraps), label content, and clarity;

- The Quality Department periodically samples from qualified products for more stringent full-dimension measurements and functional testing to ensure production process stability;

- Traceability Assurance

- Each harness is assigned a unique label serial number, traceable through the labeling system. This enables rapid identification of the source and isolation of problematic products in the event of an issue.

Can we visit your factory?

Of course, we welcome you to visit our factory at any time. Please email or call us to let us know if you have a trip planned.

How can we ensure the quality and traceability of components?

Our procurement channels source raw materials directly from original equipment manufacturers (OEMs) or authorized distributors. Each batch of components features a unique batch number and original factory packaging, enabling full traceability to the source. Prior to collaboration, we will send all relevant raw material information for your confirmation, ensuring you have complete transparency and confidence in the materials we use.

What is the difference between molded cable assemblies and cable assemblies?

Molded cable assemblies integrate cables and connectors into a single unit using rigid plastic or rubber materials. This durable, moisture- and dust-resistant construction makes them ideal for industrial, military, or outdoor applications.

Overmolded cable assemblies enhance stress resistance (such as bending or twisting) by encapsulating existing cables and connectors within a flexible protective layer. This reinforcement maintains harness flexibility, making them highly suitable for dynamic applications like robotics, medical equipment, or environments involving repetitive motion.

Service

We provide comprehensive solutions with custom services, including:

- Wire cutting, stripping, crimping, soldering, and termination

Wire harness assemblies - Precision machining, including 0.1mm-level length tolerances, specialized bend angles, and non-standard terminal crimping

- Value-added services encompass: 24-hour quotation response, custom wire gauges, product appearance and functional testing, and production support for diverse product types.

Blog

MIDI Cables: A Comprehensive Guide to Choosing the Best Cables

MIDI cables have revolutionized music production and live performance scenarios, connecting various synthesizers,

Automotive Switches: 5 Common Types

Understand the five common types of automotive switches, their core functions, and characteristics

Custom Lighting Harnesses: The Ultimate Guide

Custom lighting harnesses are professionally designed integrated solutions tailored to specific application requirements.